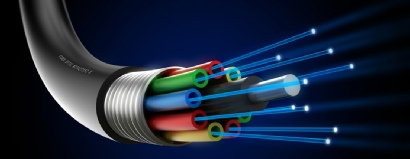

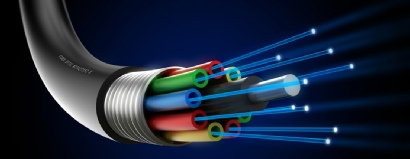

Fusion splicing is the process of fusing or welding two fibers together usually by an electric arc. It is the most widely used method of splicing as it provides for the lowest loss and least reflectance, as well as providing the strongest and most reliable joint between two fibers.

Mechanical splices are used to create permanent joints between two fibers by holding the fibers in an alignment fixture and reducing loss and reflectance with a transparent gel or optical adhesive between the fibers that matches the optical properties of the glass. Mechanical splices generally have higher loss and greater reflectance than fusion splices, and because the fibers are crimped to hold them in place, do not have as good fiber retention or pull-out strength. The splice component itself, which includes a precision alignment mechanism, is more expensive than the simple protection sleeve needed by a fusion splice.

Mechanical splices are most popular for fast, temporary restoration or for splicing multimode fibers in a premises installation. They are also used - without crimping the fibers - as temporary splices for testing bare fibers with OTDRs or OLTSs.

All JBC Inc. Fiber Technicians are certified through the FOA. The FOA is recognized by the department of Labor as the national standard for certifying professional fiber splicers. JBC Inc. Currently holds 4 individual fiber certifications. By clicking on each you can read more about them. CFOT CFOS/T CFOS/S CFOS/O : In Summary, these certifications cover Inside Plant, Outside Plant, Splicing and Testing.